Intelligent design system It is a design management system tailored to the characteristics of the discrete manufacturing industry, with product design as the core. Unifies the design work process focusing on the following functions: • Employs a parametric design concept; • Integrates 3D design software; • Incorporates product design and R&D; • Manages product change and management; • EPDM data collection and management; • Process routing maintenance and management; • Contract processing; • Accurate interface data provided to the ERP system.

Introduction

It integrates R&D, product serialization, contract processing, design change, process routing design, purchase quotation, packing design, data preparation and other business functions all on one unified information management platform. This is accomplished through the parameterization, modularization, 3D improvements, realizing standardization of design data, automation of non-standard designs, system operation integration and rationalization of business processes.

It establishes an unified R&D management platform between multiple factories, unifying product design, parallel design, manufacturing, packing, procurement data preparation, shortening product standardization cycle and breaking down barriers to design and manufacturing. The parameterization of data during the design, manufacturing and procurement processes ensure the level automation during contract processing is enhanced.

Unique Advantages

-

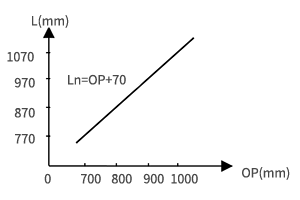

Parametric design, product size scope from a scatter chart to an expanded line chart, reducing non-standard requirements and broadening the scope of managing automatic contracts.

-

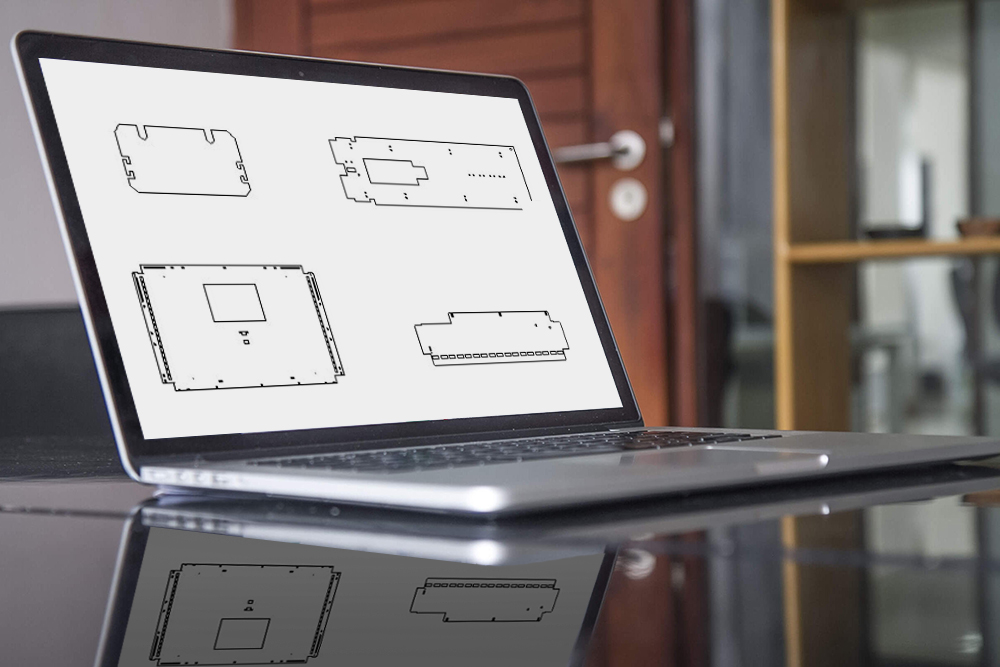

3D model drive automatically generate drawings, sheet metal expansion diagrams, reducing the design error rate by 20%.

-

3D model real-time verification, linking the design formula and model data, with real-time verification of the accuracy of design formula and accessory products R&D design.

-

Logic version management, undertakes contract processing according to the automatically selected specified time, calculates the corresponding version logic, meets the batch shipping requirements of companies.

-

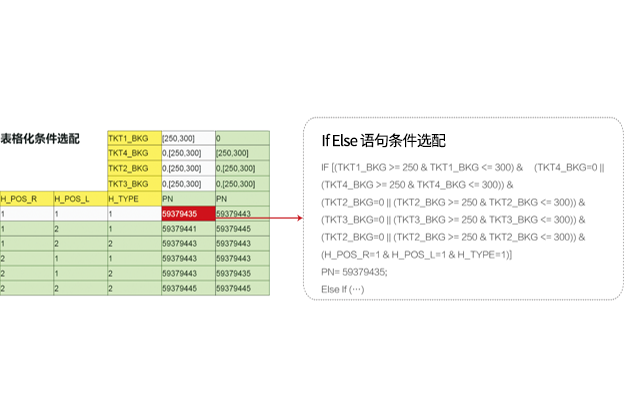

Design logic does not need to be translated, design configuration is completed without programming, the design results are directly sent to contract processing, without requiring someone in PLM or ERP to edit twice.

-

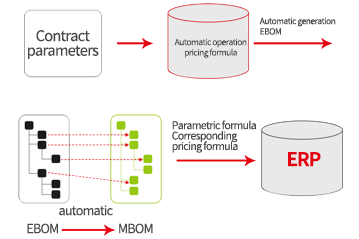

EBOM is automatically transferred into MBOM, automatically generate packaging BOM, process routing, material BOM, procurement BOM and other data, and can be transferred to ERP.

Our system enables multiple plants spanning the globe to prepare their own manufacturing data simultaneously using one system. This allows for manufacturing, production planning and supply chain data to be shared and integrated. In addition, our intelligent system allows for the global storage of product data, which then can orchestrate a high-capacity of work orders and instruct multiple manufacturing plants to produce across a company’s network, reducing the amount of repeated work, greatly improve efficiency, and ultimately cut manufacturing and logistics overhead.

Company Info

Through our deep understanding of the discrete manufacturing industry, we bring technological innovation to the industry.

Products Overview

Full life cycle business

Industry Insight

How much do you know about the digitalization of the industry? Find out what the technological developments have transformed the industry.

Events

Check the schedule of industry meetings, events, and seminars. You'll have the opportunity to enhance your professional network at these meetings and events.

ZXtech (Shanghai) Co., Ltd.

ZXTech has been dedicated to the intelligent digitalization of discrete manufacturing industry for more than 20 years, and is the world's leading supplier of data-driven solutions. Based on its experience accumulated in the elevator industry, ZXtech has expanded to other discrete manufacturing industries such as air-conditioners, electrical motors, and assembly equipments. Its products and services cover the full life cycle of marketing, sales, design, installation and maintenance, and personnel training.